The Ultimate Guide to Heat Shrink Tubing Wire Label Printers

Introduction

In today’s fast-paced business environment, efficient labeling solutions are essential for maintaining organization and ensuring operational success. Among the myriad of tools available, the heat shrink tubing wire label printer stands out as a versatile and reliable device for professionals in various industries. In this article, we will delve into the features, benefits, and applications of heat shrink tubing wire label printers, providing you with comprehensive insight into how they can transform your business practices.

What is a Heat Shrink Tubing Wire Label Printer?

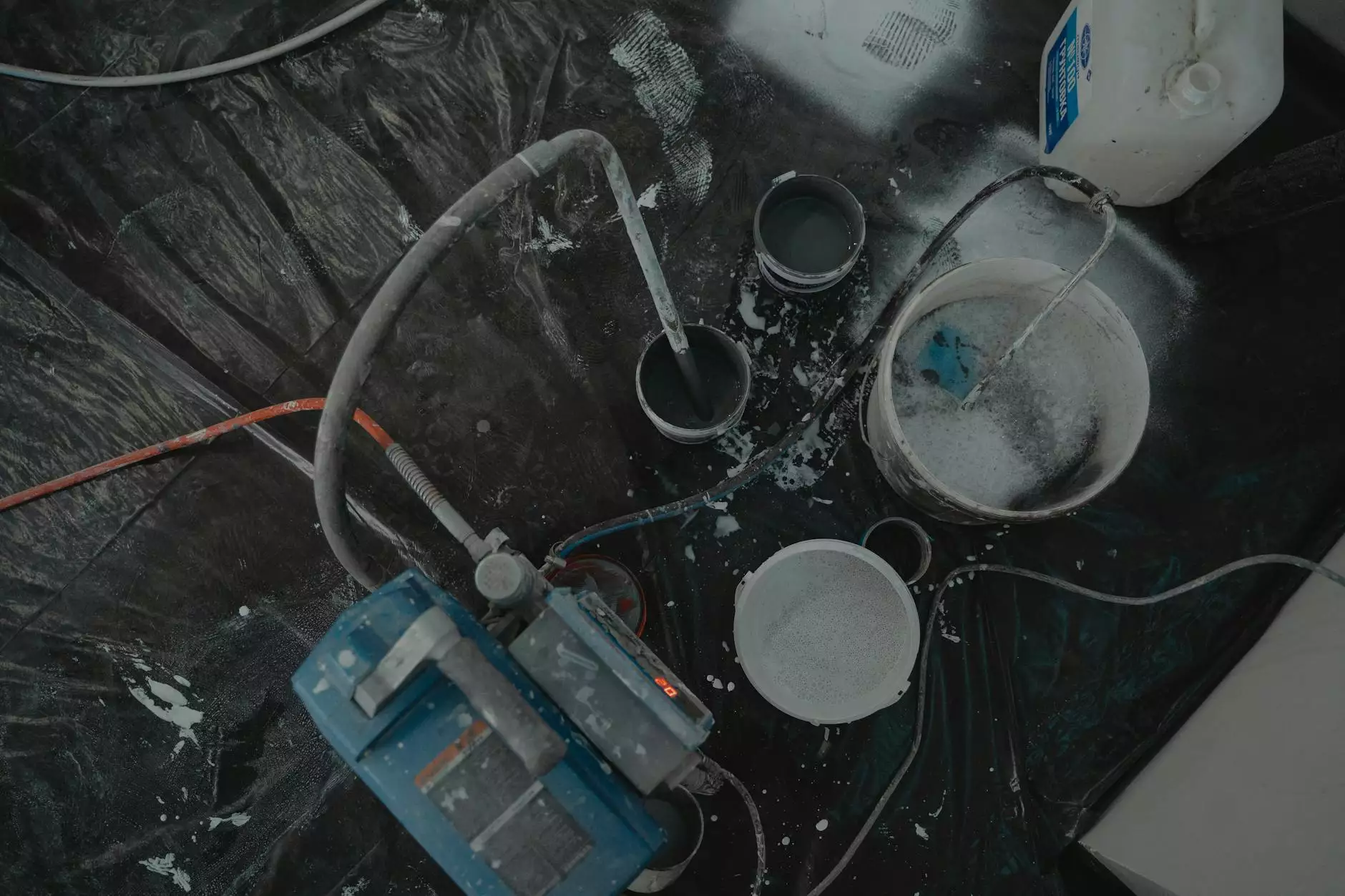

A heat shrink tubing wire label printer is a specialized printer designed for creating labels that are printed onto heat shrink tubing. This tubing, when heated, contracts to form a tight seal around the labeled object, making it ideal for wires and cables. These printers typically offer high-resolution printing, durable materials, and customizable label sizes, catering to the needs of various electronic and industrial applications.

Key Features of Heat Shrink Tubing Wire Label Printers

- High-Quality Printing: Most printers provide exceptional print quality with sharp, clear text and graphics, ensuring your labels are easily readable.

- Durability: Labels produced are resistant to fading, moisture, and abrasion, making them suitable for demanding environments.

- Customization: Users can create labels of various lengths, fonts, and sizes, tailored specifically to their projects.

- Ease of Use: With user-friendly interfaces, these printers often come with software that allows for easy label design and printing.

- Wide Compatibility: Many heat shrink label printers are compatible with multiple types of tubing materials to meet varied application requirements.

The Importance of Quality Labels in Business

In any business that deals with electronics or wiring, labeling is not merely an option; it is a necessity. Proper labeling ensures that all wires and cables are easily identifiable, which can save time and reduce errors in both installation and maintenance. Moreover, well-labeled equipment not only enhances safety but also improves the overall efficiency of operations. Here are some reasons why investing in a heat shrink tubing wire label printer is crucial:

- Improved Organization: Clearly labeled wires help prevent mix-ups and streamline operations.

- Increased Safety: Properly labeled wires minimize the risk of accidents or misinterpretations during installation and maintenance.

- Regulatory Compliance: In many sectors, proper labeling is required to comply with safety standards and regulations.

- Enhanced Professionalism: High-quality labels contribute to a more professional appearance, which can impress clients and stakeholders.

Applications of Heat Shrink Tubing Wire Label Printers

The versatility of heat shrink tubing wire label printers allows them to be utilized across various industries. Here are some key applications:

1. Electronics Manufacturing

In electronics manufacturing, each component needs to be clearly labeled to maintain organization during assembly. A heat shrink tubing wire label printer ensures that each wire is identifiable with minimal effort, facilitating efficient production processes.

2. Telecommunications

Telecommunications companies frequently deal with numerous cables and wires. Labeled wires help technicians quickly identify connections and troubleshoot issues, significantly speeding up repair and installation times.

3. Automotive Industry

In automotive applications, heat shrink tubing labels help in organizing wiring harnesses, ensuring that every wire is matched correctly to its respective component, which is crucial for the safety and functionality of vehicles.

4. Home and Office Installation

For professionals involved in home theater installations or office wiring, utilizing a heat shrink tubing wire label printer enables precise and professional labeling that enhances the overall aesthetic and functionality of the setup.

Choosing the Right Heat Shrink Tubing Wire Label Printer

When selecting a heat shrink tubing wire label printer, several factors should be taken into consideration:

- Print Speed: Depending on your workflow, the speed of the printer may be a critical factor. Higher-speed printers can greatly enhance productivity.

- Labeling Software: Look for printers that come bundled with easy-to-use software for label design, which can simplify the creation process.

- Connectivity Options: Modern printers often feature USB, Bluetooth, or Wi-Fi capabilities, allowing for seamless integration with your existing systems.

- Cost of Consumables: Consider the long-term costs associated with replacement tubing and ink, ensuring that the printer remains cost-effective over time.

- Customer Support: A manufacturer offering robust customer support can be invaluable, especially when troubleshooting issues or needing assistance with the software.

Benefits of Using Heat Shrink Tubing Wire Label Printers

Using a heat shrink tubing wire label printer provides numerous advantages for businesses:

1. Cost-Effectiveness

By investing in a heat shrink tubing wire label printer, businesses can produce labels in-house, avoiding the costs associated with outsourcing labeling tasks. This results in significant savings, particularly for large-scale operations.

2. Increase in Efficiency

Creating labels on demand eliminates wait times associated with ordering pre-made labels, thus increasing operational efficiency. Labeling can be done as needed, ensuring that wires and cables are labeled right before use.

3. Enhanced Customization

Modern printers allow for extensive customization options. Businesses can create unique labels tailored to specific projects, ensuring that every label meets the needs of the application.

4. Environmental Benefits

By producing labels on a need-only basis, businesses can reduce waste. Many manufacturers are also moving towards eco-friendly materials, further contributing to sustainability efforts.

Real-World Case Studies

To illustrate the impact of heat shrink tubing wire label printers, let’s explore a few case studies:

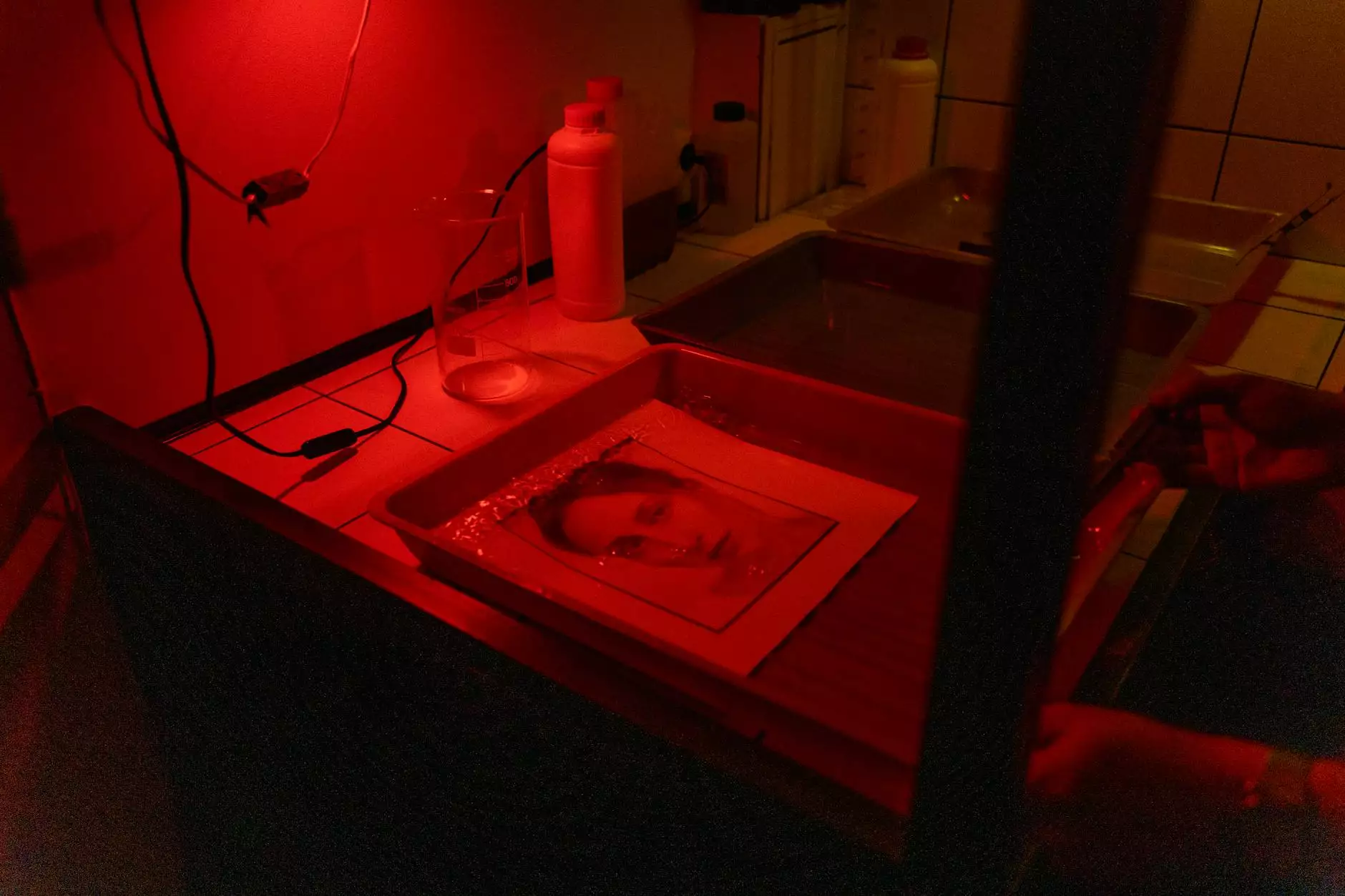

Case Study 1: Electronics Assembly Line

A large electronics manufacturer integrated heat shrink tubing wire label printers into their assembly line. By doing so, they reduced errors in wiring configurations by 30%, significantly improving assembly speed and lowering rework costs.

Case Study 2: Telecommunications Repair Service

A telecom repair company found that using a heat shrink tubing wire label printer reduced their troubleshooting time by 25%. Technicians were able to quickly identify wires, leading to faster service calls and increased customer satisfaction.

Case Study 3: Automotive Industry Adoption

In the automotive industry, a leading manufacturer reported enhanced organization of their wiring systems after implementing these printers, leading to a decrease in production delays and a more streamlined quality control process.

Conclusion

Investing in a heat shrink tubing wire label printer can significantly enhance organizational efficiency, safety, and professionalism in numerous industries. From electronics to telecommunications and beyond, the benefits of high-quality labeling solutions are clear. As businesses strive to improve operational efficiency, effective labeling remains a crucial factor in achieving success. Understanding the capabilities and applications of heat shrink tubing wire label printers can empower your business to make informed decisions, ultimately leading to optimized processes and increased productivity.

Call to Action

If you are ready to take your labeling solutions to the next level, consider exploring the range of heat shrink tubing wire label printers at DurafastLabel.com. Equip your business with the tools necessary to thrive in today's competitive landscape and witness the transformation in your operational efficiency.